Vibratory Tumble Breaders | Breading Machines from Food Process Systems | Made in the USA

Vibratory Tumble Breaders

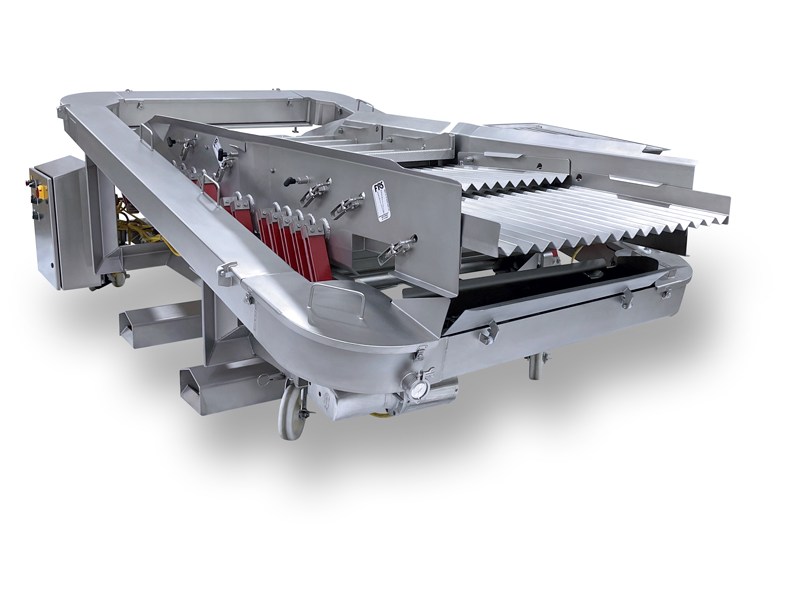

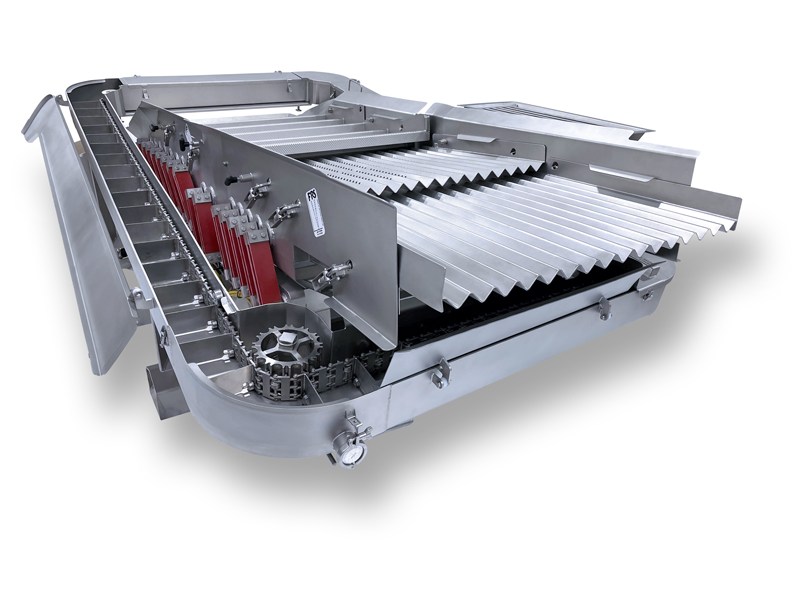

Standard Vibratory Tumble Breader

Great Coverage without the Drum

The FPS Tumble Breader flips and tumbles product over a series of steps to coat product with up to 12 percent pickup in the first position on the breading line.

This breading equipment adjusts to match your line’s speed and capacity. Intake and outflow are both accomplished at line width.

The slotted discharge pan is customizable to spread or lane product while the vibratory action also removes excess breading or flour to the recycle conveyor. These efficiencies result in shorter production lines and cleaner fryer oil.

The Tumble Breader’s tilt-up, removable pans not only make sanitation a breeze, but exchanging them for flat pans makes changeover from whole-muscle to formed product quick and easy. Breading empties quickly through the Tumble Breader’s all stainless steel recycle system which also facilitates speedy changeovers and easy cleaning.

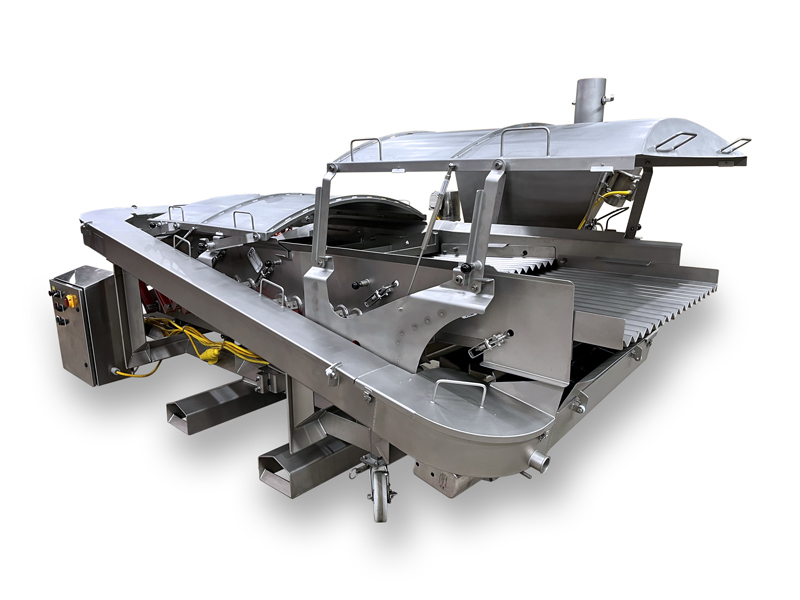

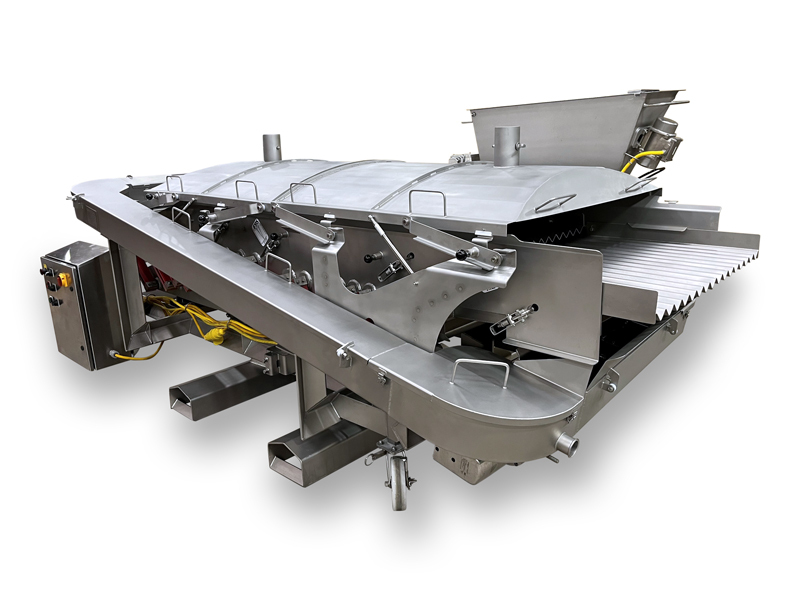

Vibratory Aligning Tumble Breader

The FPS Aligning Tumble Breader includes all the features and advantages of the FPS Tumble Breader, plus one more. At the discharge, this versatile breading machine adds a second, less-aggressive shaker with dual alignment pans to straighten, lane, and increase space between product for further processing.

This patented application of vibratory technology reduces product fold-overs and marriages and greatly reduces the number of inspectors needed to sort, fix, or discard them.

The slotted alignment pan recovers unused breading to FPS’s augerless, all stainless steel recycling system. Used in all FPS Breaders, this patented, gentle-on-breading design recirculates the widest variety of coatings without crushing to create consistent coverage with less waste.

Both FPS Tumble Breader models are made in the USA and feature:

- USDA- and WDA-compliant designs for direct food contact.

- Heavy-gauge 304 stainless steel construction suitable for ready-to-eat products.

- Tilt-up pans and hinged covers that provide complete interior cleaning access

- Stainless steel, washdown AC drives

- Stainless steel recycle belt

- Stainless steel retractable dust cover

Custom options include:

- Product metering conveyor

- Bulk coating hopper with sensor-activated infeed conveyor

- Interchangeable discharge pans to sift, spread, and align product.